DIGITAL SOLUTIONS

Operations & Maintenance

Drilling analysis, situational awareness, predictive maintenance, production optimization, turnarounds, technical surveillance, planning and scheduling, performance monitoring, remote operations, and plant optimization.

Emissions Management

Process stabilization, energy consumption tracking, carbon footprint reporting, GHG emissions monitoring, leak detection, and route optimization.

Simulation System

Logic testing, pre-start-up verification, operator and technical personnel training, engineering studies, process simulations, and testing of start-up, stop, and emergency stop sequences.

WHY OUR SOLUTIONS?

Jiyu Automation was established with a clear mission: to deliver advanced industrial automation solutions tailored to the needs of the automobile, process, and oil and gas industries. Utilizing state-of-the-art technology and a wealth of expertise, we are dedicated to helping engineers and operators optimize processes, overcome industry challenges, and seize opportunities. Whether it’s enhancing operational efficiency, reducing costs, improving safety, or driving innovation, we are committed to providing reliable solutions that address critical demands such as process optimization, energy management, system reliability, and scalability.

Automobile Industry

In the automobile industry, industrial robotics plays a crucial role in streamlining production lines, reducing labor costs, and ensuring high levels of precision. At Jiyu Automation, we provide robotics solutions that are optimized for tasks such as welding, assembly, painting, material handling, and inspection. Robots are deployed to perform repetitive, high-precision tasks, improving the overall production process by ensuring consistent product quality and reducing human error.

Our industrial robots work seamlessly alongside other automation systems to support the manufacturing of vehicles, from the assembly of individual components to the final inspection stages. Additionally, we integrate advanced technologies such as machine vision and AI to enable robots to adapt to changing conditions on the production line, ensuring maximum flexibility and efficiency.

Process Industry

The process industry, which includes sectors like chemicals, pharmaceuticals, food and beverage, and manufacturing, demands high levels of automation to optimize operations, ensure product consistency, and minimize downtime. Jiyu Automation offers robotics solutions that handle tasks such as material handling, mixing, filling, packaging, and inspection in process industries.

Industrial robots in the process industry are designed to work in hazardous environments, where human intervention might be unsafe. These robots can operate in high temperatures, toxic environments, or areas with high risks of contamination, thereby improving worker safety. Our robots are highly customizable to meet the specific needs of each process, and they are integrated with other systems like SCADA and PLCs for seamless operation.

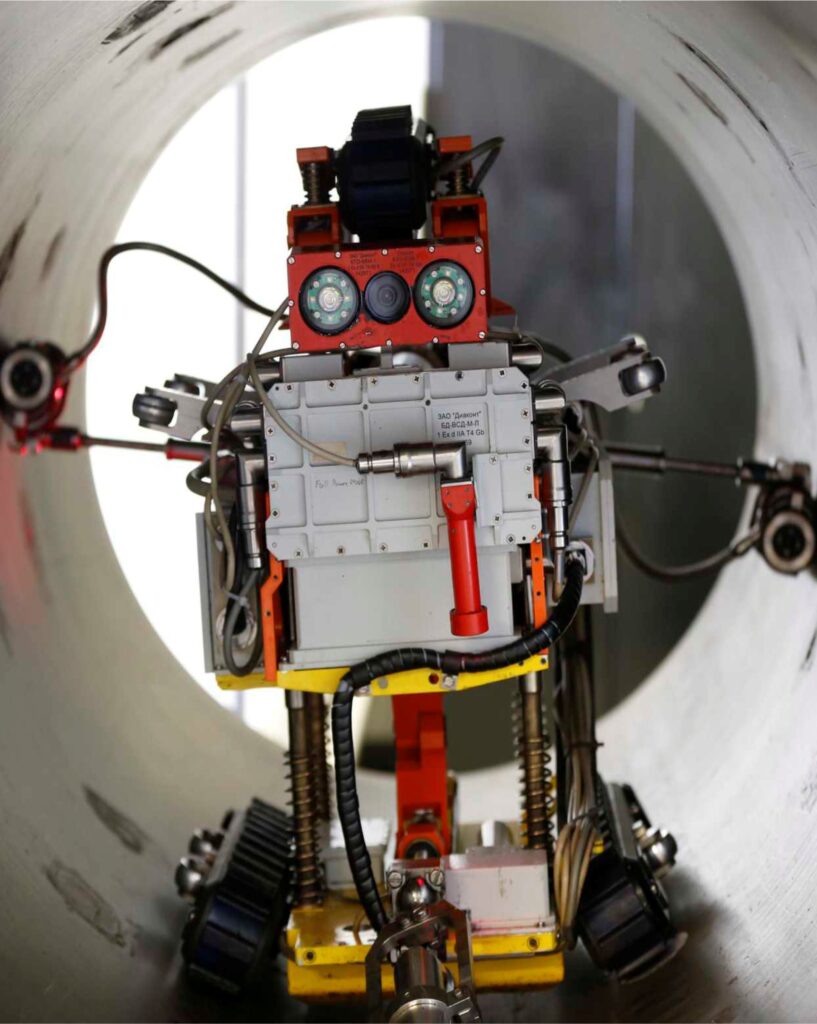

Oil and Gas Industry

In the oil and gas industry, robotics is transforming operations by enhancing safety, efficiency, and reducing operational risks. Jiyu Automation provides specialized robotic systems for tasks such as pipeline inspection, offshore drilling, maintenance, and hazardous material handling. Industrial robots in this sector help mitigate the risks associated with working in extreme environments, such as deep-sea oil rigs or remote locations with harsh weather conditions.

Robotic systems are used for remote monitoring and maintenance tasks, reducing the need for human workers to perform dangerous jobs. For example, our robots can conduct inspections of pipelines, detect leaks, and ensure structural integrity, all while minimizing downtime. Additionally, robotics systems can handle the manipulation of hazardous materials, improving safety and reducing the potential for accidents.