Efficient Oil, Water, and Sand Separation in Surface Facilities

Oil and gas automation involves the integration of advanced technologies across various stages of the oil and gas value chain, including drilling, production, transportation, storage, and refining. It includes automation software for remote operations and physical technologies like robotics and sensors for improved processes.

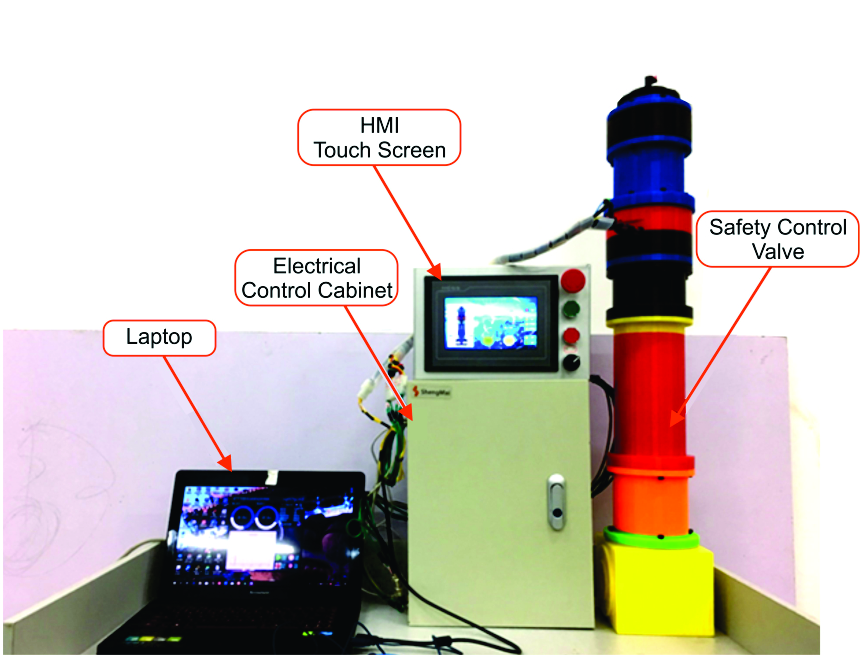

In surface facilities, SCADA systems are applied to monitor and control the separation of oil, water, and sand by regulating pressure, temperature, and flow conditions, ensuring efficient and continuous operation. Beyond IT solutions, automation ensures regulatory compliance, optimizes performance, and drives operational efficiency throughout the oil and gas value chain.

DEDICATED Solutions

Jiyu Automation helps oil and gas companies optimize costs, maximize uptime, and enhance asset value through advanced automation and digital solutions. Utilizing cloud technology, mobility, and analytics, we provide real-time insights for quick issue resolution and improved efficiency. Our expertise spans measurement technologies, control systems, and analytical tools, supporting operations from reservoir to refinery. By mitigating risks and optimizing performance, we empower clients to stay competitive in a rapidly evolving industry.

RESEARCH AND PATENTS

Our team have developed the core technologies of the system, which have been granted 50 Chinese invention patents, 1 U.S. patent, and 3 Australian patents. The research outcomes have been featured in prestigious journals, including IEEE Transactions on Neural Networks and Learning Systems, IEEE Transactions on Systems, Man, and Cybernetics: Systems, Reliability Engineering & System Safety, Expert Systems with Applications, Ocean Engineering, International Journal of Control, Automation and Systems, and others.

ADVANCED FAULT DIAGNOSIS TECHNOLOGY

We developed a fault re-prediction model for subsea equipment using the Wiener process and dynamic Bayesian networks. Powered by the expectation maximization algorithm, the model achieves high accuracy, with predicted RUL deviating less than 3.5% from actual values. It successfully forecasted failures in the subsea BOP stack and control system, proving its effectiveness in predictive maintenance. This approach enhances reliability and minimizes downtime.

OPTIMIZING OFFSHORE WELL CONTROL

We propose a tenacity-centered, condition-based maintenance strategy for offshore oil well control equipment to reduce costs and operational risks. By optimizing availability and RUL, this approach minimizes downtime and extends equipment life. Implementation has led to a 27% reduction in maintenance costs and a 25% increase in equipment availability, even under harsh conditions. This strategy enhances reliability, efficiency, and sustainability in subsea operations.

OFFSHORE SAFETY AND EMERGENCY RESPONSE

We have conducted extensive debugging and testing to ensure a reliable system, which has been successfully deployed on key offshore platforms, including South China Sea No. 10 and No. 8, and the Endeavour drilling platform. Notably, it has been applied to China’s first subsea emergency well packer, a major offshore safety milestone. Featured on CCTV, the system enhances the safety, reliability, and efficiency of offshore oil and gas operations, serving as a critical safeguard.