C-Innovation (C-I), renowned for its Riser-less Light Well Intervention (RLWI) technology, has achieved a significant breakthrough in deep water well intervention. C-I has developed an innovative hydraulic intervention solution to address the limitations of traditional intervention methods for wellhead operations beneath deep water drilling platforms. This advanced method enables safe and efficient well intervention from an offset position while minimizing disruptions to production facilities. C-Innovation has developed a hydraulic intervention solution that successfully performs deep water well interventions from an offset position through its Well Service Jumper (WSJ) system. At the core of this innovative approach is the Riser-less Stimulation Tool (RST), which works in combination with high-pressure hoses and flexible dynamic positioning operations. This method enables the completion of complex well interventions without disrupting production facilities.

The solution integrates advanced technology to ensure efficiency and reliability while addressing the unique challenges of deep water operations.

Challenges in Deepwater Well Intervention

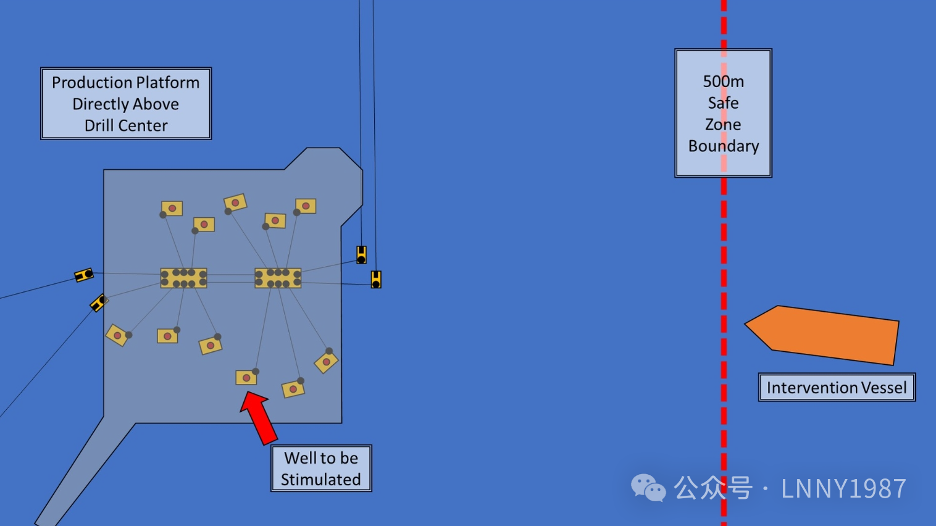

Deepwater well intervention faces a variety of challenges, especially when dealing with “restricted wells” located beneath production facilities. One major issue is the high costs associated with Direct Vertical Access (DVA) systems. Traditional intervention techniques often necessitate repositioning platforms or deploying DVA systems, which result in considerable equipment expenses and interruptions to production. The durability of chemical injection systems poses a concern, as production system materials may not be designed to withstand stimulation fluids such as acids or chemical treatments, leading to material degradation and shortened system lifespan. Furthermore, space constraints on production facilities make it difficult to accommodate the necessary intervention equipment. This is particularly problematic for smaller operators on shared platforms, where limited facility space and priority allocation can restrict the ability to carry out intervention plans.

Key Contributions in deep water well operations

C-Innovation’s hydraulic intervention solution incorporates several key components that contribute to its effectiveness in deep water well operations. The Well Service Jumper (WSJ) is a single high-pressure hose that can extend up to 750 feet, connecting the Riserless Stimulation Tool (RST) to the wellhead tree (XT). It is installed using a remotely operated vehicle (ROV) and is designed to adapt to complex subsurface environments. The RST itself is a subsea manifold that provides high-pressure fluid injection capabilities and well control barriers. Equipped with a lateral outlet adapter, it can be positioned on a mud mat on the seabed, avoiding direct placement beneath production facilities. The flexible downline and hybrid catenary system includes a high-pressure hose that connects the wellhead tree (XT) to the RST, with a length of up to 1,050 feet, ensuring a safe operational distance between the intervention vessel and the facility. The RST is installed at a designated location on the seabed with the help of an ROV, and the high-pressure hose connects the intervention vessel to the RST for efficient operations. Dynamic positioning and automated controls guarantee stable equipment performance even in challenging sea conditions. Additionally, the segmented hose design simplifies maintenance and repairs, enhancing operational efficiency and minimizing downtime.

Application Scenarios and Achievements

C-Innovation’s hydraulic intervention system has been successfully applied in several deepwater projects in the Gulf of Mexico, showcasing its adaptability in a variety of scenarios. These include wellbore stimulation and cleaning, where high-pressure fluids are used to clear obstructions in the wellbore, greatly improving production capacity. The system also facilitates chemical injection, where acidic or other treatment fluids are introduced to enhance reservoir permeability and boost performance. Additionally, it supports multi-well intervention, enabling operations on multiple wellheads within a single drilling center without the need to recover and redeploy equipment. This system has successfully completed interventions on seven high-output wells, injecting over 9 million gallons of stimulation fluid. Its flexible, modular design allows operators to carry out complex intervention tasks in a fraction of the time.

The system offers several technical advantages, including significant cost and time savings by eliminating the need for traditional Direct Vertical Access (DVA) systems, reducing deployment costs, and minimizing production downtime. It also enhances safety through dynamic positioning technology and remote operation, which lower operational risks and ensure stable performance even in harsh sea conditions. The system’s high flexibility comes from its modular design and segmented hose components, which adapt to a variety of complex well conditions and simplify maintenance. Furthermore, the riser-less design minimizes environmental impact, contributing to sustainable development efforts.

Expert Insights

C-Innovation engineers Nathan Wolford and Kevin Knight highlighted the transformative impact of their hydraulic intervention technology on deepwater well operations. Wolford stated, “By enabling offset position operations, we have significantly reduced facility interference while expanding the scope of safe operations.” Knight added, “The development of this system reflects our deep understanding of complex deepwater operations and lays a solid foundation for future technological advancements.” C-Innovation’s hydraulic intervention technology has overcome traditional deepwater intervention limitations, offering operators a flexible, efficient, and safe solution. As the technology continues to be refined, it is poised to set new industry standards for global deepwater oil and gas development, delivering significant economic and production benefits to operators.