FUTURE OF AUTO SECTOR

Industrial automation has become essential in the automobile sector due to the increasing demand for higher production rates, improved quality, and cost-efficiency. As consumer expectations rise, manual processes are no longer sufficient to meet the complexity and speed required in modern manufacturing. Automation allows for faster production cycles, consistent quality, and precise control over assembly processes, reducing human error and minimizing waste.

Additionally, automation enhances safety in hazardous environments, optimizes resource utilization, and supports the integration of new technologies like electric vehicles and smart manufacturing. In today’s competitive market, industrial automation is no longer just a choice but a necessity for automobile manufacturers to stay ahead.

AUTOMOBILE ADVANCEMENT SEGMENTS

COMPONENTS, FABCRICATION AND ASSEMBLY

- Guarantee the quality of exterior, interior, underhood, engine, and powertrain components while enhancing the sustainability of production processes.

- Optimize flexibility and lower costs in powertrain assembly, final assembly, part cleaning, and body and paint applications with our advanced control solutions.

- Leverage high-precision plastic and metal welding technologies for assembling lightweight EV components and data circuits critical to modern autonomous vehicles.

- Increase throughput, minimize downtime, and maintain quality by enhancing machine performance and optimizing energy consumption during tire manufacturing and cutting processes.

The automobile industry is working toward cleaner, more adaptable, and flexible production of gas-powered and electric vehicles. Whether you’re manufacturing individual components or complete vehicles, Emerson is here to support you. Our innovative solutions, including advanced plastic and metal welding technologies, cutting-edge pneumatics, actuation and controls, and software with Floor to Cloud connectivity, are designed to help you achieve your goals for adaptability, productivity, efficiency, and sustainability.

APPLIED SOLUTIONS AND PRODUCTION

- Deliver innovative designs and superior finishes that captivate end customers and surpass their expectations.

- Cut production costs with advanced, clean joining technologies for exterior parts, enabling greater flexibility in product design.

- Enhance fuel efficiency by reducing vehicle weight while ensuring durability and corrosion resistance.

- Reduce energy consumption and thermal stresses on components for optimized performance and reliability.

- Enhance stability, control, and drivability with advanced air suspension components.

We are your trusted partner for all solutions and production needs. Our certified engineers bring years of experience across various industries and applications, ensuring that your company fully leverages the benefits of robotics technology. In specific areas, we also serve as a system integrator and general contractor, offering expert advice on quality and technology. We manage system vendors and design component-specific tools and workholding systems to seamlessly integrate with your robotics solutions.

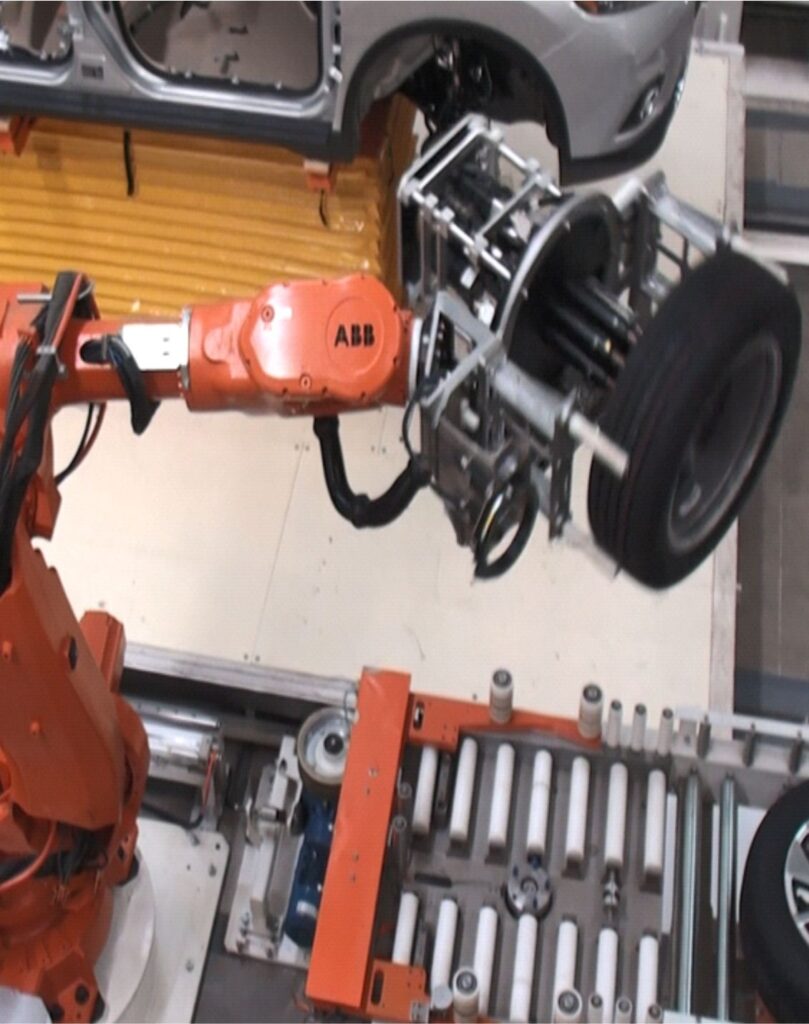

CUSTOMIZED ROBOTICS SOLUTIONS

Industrial robots are versatile, high-tech, and cost-effective, capable of performing a wide range of tasks. However, a single robot alone may not be sufficient for your needs. What you truly require is a comprehensive, tailored solution designed for your specific applications, such as welding, sorting, or more. Jiyu Automation has been providing industries with customized robotic solutions for years. We offer product-agnostic solutions, working with leading robotic brands like KUKA, ABB, and FANUC to address a variety of applications.

When you choose our robotics solution, you can be confident that it will deliver exactly what you need, with a strong return on investment. Our 360° service range includes everything from extensive pre-installation testing to ongoing maintenance and servicing. We also create custom control software and design component-specific tools and workholding systems, ensuring smooth integration and optimal performance.

- Our Services for Your Automation Needs

Consulting – Our experts provide in-depth consultations to help you identify the right solutions for your specific requirements, ensuring optimal performance and efficiency.

Design and Planning – We work closely with you to design and plan customized automation systems that meet your operational goals, offering innovative and effective solutions.

Programming and Commissioning – We manage the programming and commissioning process from start to finish, ensuring that all systems are correctly set up and fully operational.

Modernization – We offer modernization services to upgrade your existing systems with the latest technologies, improving performance and extending system lifespan.

Maintenance – We offer ongoing maintenance services to ensure the continued efficiency and reliability of your automation systems.

Training – We provide comprehensive training programs for your team, ensuring they are fully equipped to operate and maintain automation systems effectively.

After-sales Service – Our commitment extends beyond installation, offering robust after-sales support to help you with any future needs or challenges.

- Dedicated and Innovative Solutions

WE ARE DEDICATED TO HELPING ENGINEERS AND OPERATORS OPTIMIZE PROCESSES, OVERCOME INDUSTRY CHALLENGES, AND SEIZE OPPORTUNITIES. WHETHER IT’S ENHANCING OPERATIONAL EFFICIENCY, REDUCING COSTS, IMPROVING SAFETY, OR DRIVING INNOVATION, WE ARE COMMITTED TO PROVIDING RELIABLE SOLUTIONS THAT ADDRESS CRITICAL DEMANDS SUCH AS PROCESS OPTIMIZATION, ENERGY MANAGEMENT, SYSTEM RELIABILITY, AND SCALABILITY.

SCADA MONITORING AND CONTROL SYSTEM

A SCADA (Supervisory Control and Data Acquisition) system is a vital component of industrial automation in automobile manufacturing, providing centralized control and monitoring of production processes. SCADA systems collect real-time data from sensors, robotic arms, conveyor belts, and other machinery, enabling operators to track performance, detect anomalies, and optimize efficiency. By integrating SCADA with AI and machine learning, manufacturers can implement predictive maintenance, reducing downtime and preventing costly equipment failures. Additionally, SCADA systems enhance plant safety by providing automated alerts and responses to potential hazards, ensuring a smooth and reliable production workflow.

DIGITAL TWINNING TECHNOLOGY

Digital twinning technology has transformed automobile manufacturing by creating virtual replicas of physical systems, enabling real-time simulation and analysis. A digital twin allows manufacturers to monitor, test, and optimize production processes without disrupting actual operations. This technology improves decision-making by simulating different scenarios, predicting potential failures, and suggesting preventive maintenance strategies. In automobile production, digital twins can be used for vehicle design, assembly line optimization, and performance testing, leading to reduced development time and improved efficiency. The integration of IoT and AI further enhances digital twins, providing continuous feedback loops that refine manufacturing processes and ensure high-quality outputs.

MECHANICAL TESTING FACILITY

A mechanical testing facility is a critical component of automobile industrial automation, ensuring that materials and components meet industry standards and performance expectations. These facilities use advanced robotic testing equipment, high-speed sensors, and automated stress analysis systems to evaluate factors like durability, tensile strength, impact resistance, and fatigue behavior of vehicle parts. Automated testing processes help manufacturers identify potential defects early in the production cycle, reducing waste and improving product reliability. By integrating AI-powered analytics, mechanical testing facilities can provide predictive insights, allowing manufacturers to proactively address material weaknesses and enhance the safety and longevity of automotive components.